Airships, also called dirigibles, served as an alternative to transoceanic travel by boat in the early 1900s. However, the future of dirigibles as transportation vehicles ended when the Hindenburg, a giant hydrogen-filled dirigible, burst into flames over Lakehurst, N.J., in 1937. Once airplanes were recognized as safe for passenger travel, few saw a need for commercial airships.

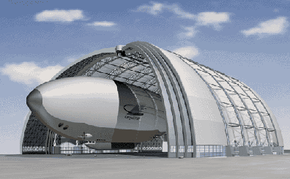

Most airships you see today are used as flying billboards, like the Goodyear or Fuji blimps you see hovering above major sporting events. But airships may soon provide more than advertising. One German company is bringing back the mammoth dirigibles of the early 20th century to fill a niche in the transportation industry. CargoLifter AG is investing in the idea that dirigibles have an advantage over other forms of transportation. The company says that its giant CL 160 airship can reach areas that are too difficult to reach by train, truck or current cargo ships. And they can haul more cargo than even the biggest heavy-cargo-transport military airplanes.

Advertisement

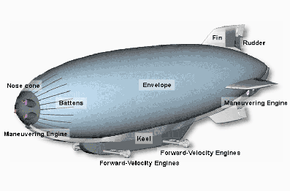

In this edition of How Stuff Will Work, you will learn how these new airships differ from their predecessors, how they will work and just why we will need these giant transport vehicles.